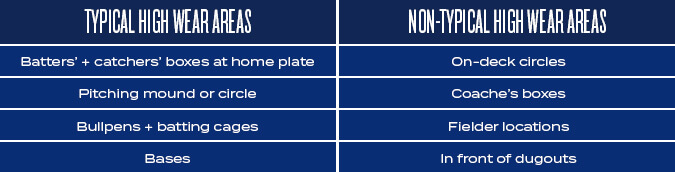

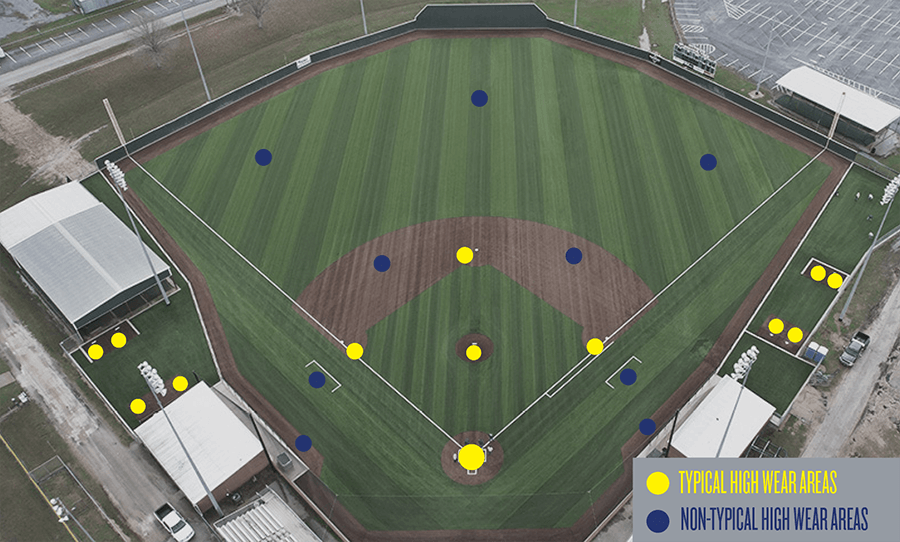

The games of baseball & softball are played in very concentrated areas on their respective fields, which sets them apart from other team sports, but also leads to special maintenance considerations for the high-wear areas.

what to expect as your field ages

As the game is played, players will kick the infill out of the turf system as they dig in at home plate and the pitcher’s rubber. Infill will be displaced at the bases and other high wear areas, with time and use leading to accelerated wear, causing fiber to layover which may split or break.

To minimize the appearance of worn areas, and delay replacement of those areas on your field, the infill should be spot dressed in these areas to minimize degradation of the turf fibers and backing, as well as use of mats and molded cleats during practice.

when it’s time to replace

Even with proper maintenance and protection, high wear areas will typically degrade before the rest of the field. Your high wear areas can be replaced at your preference for your field aesthetic and performance. A good rule of thumb is to replace once the turf and backing are worn, and a visible low spot has appeared in the high wear areas that can no longer hold new infill material when spot dressed.

what to expect when replacing high wear areas

When these areas are replaced, new turf is cut and placed in the field alongside the existing, aged turf. This may cause an “embossed” effect due to the new fibers standing upright alongside the aged fibers that have laid over. This contrast in the turf will minimize with time, use, and exposure to the elements.

glued vs. velcro inserts

We believe the best solution to high wear areas is to cut and glue the replacement areas, especially at home plate where players may be sliding across the seam.

Glued seams are more secure, and when done professionally, hold better and longer than Velcro. While these high-wear areas seem small, they are bulky and heavy to handle once the infill is taken into consideration. The infill must be removed from the turf before it can be removed from the area; any infill that falls into the Velcro may impede adhesion. Professionally replaced, glued seams provide a stronger bond and less headache for the owner staff.

As a turn-key athletic facility services provider, Paragon Sports Constructors understands the complexities of installing and maintaining synthetic sports fields. We aim to be your partner in ensuring peak performance for all your fields, all year round. Put our team to work for yours.

PDF VERSION OF BLOG POST

Paragon Sports Constructors is a turn-key contractor of natural and synthetic turf sports fields, running tracks and tennis courts based in Fort Worth, Texas. With over 40 years of sports construction experience they are one of the premier sports field and running track contractors in the South-Central United States. Paragon Sports Constructors is a member of the American Sports Builders Association who remains focused on quality construction practices, choosing to partner with top brand name manufacturers of synthetic turf and track surfacing to provide clients a consistently high-quality project from planning to first use. For more information on Paragon Sports Constructors please visit www.paragon-sports.com, or follow them on social media at LinkedIN, Twitter, and Facebook.